For companies inventory management is essential as their exists economic downturns and upturns. These trends in the economy can drastically effect company cost as holding onto inventory can become expensive. Demand is often a difficult thing to get correct. We see many companies looking to sell and reduce inventory as soon as predicted demand for goods do not pan out the way they suspected. Often times the ridding of inventory is a difficult task as the liquidity to react quickly historically is not there. Inventory can be stolen, it can become obsolete and it could be sold but many companies are now starting to believe dedicating money to inventory is a high risk with a high cost. What are the alternatives as the companies need to keep up with the demand by their clients as the cost of a shortage is even greater? Through problem solving initiatives like Six Sigma companies are more fit to react to customer demands. Theses investments in a higher level of inventory management rather than in inventory can be more competitive and eventually get more bang for the buck. Companies, in order to remain competitive, have to reevaluate where their resources are being focused and the use of technology is a resource that would be very beneficial in their future. The Ford Motor Company reportedly saved $600 million by the implementation of a Six Sigma management system. In 1999 Ford started to train their top level management then the officer group, and then the leadership group. After a year and half Ford has reportedly spent $6 million in training their several levels of management in Six Sigma. Ford rates the level of training by way of colored belts like that of a karate dojo:

Green Belt: “They receive one week of training that includes a basic understanding of how Six Sigma works and an overview of the Black Belt tools. Green Belts learn to help Black Belts do projects faster. Green Belt training allows the people who are affected by the Six Sigma projects to be able to continue to monitor and control the improvement and to do their jobs better”

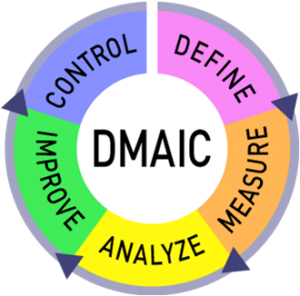

Black Belt: Process full time for two year. The training includes, “define-measure-analyze-improve-control cycle” , “mapping, cause-and-effect diagrams, failure mode and effects analysis, design of experiments, and mistake proofing”

Master Black Belts- Handpicked by upper management; describes duties are.. “My core job responsibility is to help Black Belts with the tools, eliminate road blocks and support them during the various phases of their projects”

Project Champion- Work alongside master black belts and provides them with necessary resources to complete tasks.

This sort of implementation depends on the companies dedication to customer service and by senior leadership. With such a large company as Ford Motor Company making a commitment to new, nimble approaches to inventory management there can be an example for companies of all sizes that there are very good alternatives to the negatives that come with projecting demand the traditional way.

How often do you believe companies tend to under estimate the demand in the market?

Do you feel that smaller companies have the chance to save proportionally the same level of capital a company like Ford did using something like Six Sigma?

http://www.forbes.com/sites/billconerly/2014/08/07/inventories-a-problem-for-economic-growth-and-individual-companies/

http://www.qualitydigest.com/sept01/html/ford.html