As I’m lounging on the sofa in the family room watching my husband decorate the cakes that he baked for both our moms on Mother’s Day, thoughts about how he plans the whole process are running through my head. While my husband wasn’t enthused about the interruption, I was busy asking him multiple questions regarding how to forecast future demand, how to manage quality and quantity, and finally what inventory method is used by businesses that produce wedding cakes.

Forecasting is a critical aspect of the business to effectively manage overhead costs, ingredient inventories and most importantly, volume projections to meet demand while maintaining a profitable business. To achieve desired profitability, the business should deliver a wide variety of designs at competitive prices.

In class, I had learned about five quantitative forecasting methods. The simplest method to forecast how many wedding cakes will be produced next month is looking back at the last month’s production quantity. Another forecasting model is using the moving averages forecast method. This method uses an average of the most recent periods of data to predict of how many wedding cakes need to be produced next period. For example, the bakery may use a 3-month moving average by adding the last 3-month production of wedding cakes and dividing by 3 months. However, to use this method, we would assume that the market for wedding cake demands is quite stable.

Next important aspect for a Wedding Cake business is how to efficiently manage the quantity and quality of the cakes. Higher quality of ingredients used during production will lead to a better reputation for the business and create higher customer satisfaction, leading to repeat customers. Moreover, business would save ingredient costs by purchasing larger volumes.

This reminded me of what I had recently learned in my class about product focus. Some bakery businesses focus on producing high volumes and low variety. For example, one business can focus on a niche market and produce only wedding cakes that will deliver a high volume but limited designs. But such a business will need to be highly completive in the market in order to be successful. On the other hand, another bakery might produce low volume of cakes, but cater to a much broader customer base such as birthdays, graduations, anniversaries, Bar Mitzvahs, etc.

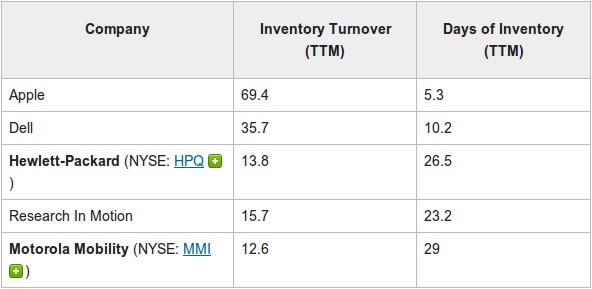

Managing inventory of raw ingredients as well as finished goods is another critical aspect that has to be closely managed. The perishable nature of the products makes it very important to effectively manage inventory of seasonal products, while maintaining stocks for rush orders. Also, inventory management is crucial in maintaining business profitability by reducing waste of both raw ingredients and expired finished products.

Although I learned a great deal regarding the wedding cake industry from my husband, I”m still left with a few questions: What is the best way to forecast wedding cakes? What process strategies should be used by bakeries? Would it be more profitable to use process focus or mass customization strategy?

http://smallbusiness.chron.com/examples-management-strategies-cake-bakery-business-12208.html