Apple, Inc. is one of the largest, most innovative companies in the world, selling not only electronic gadgets for users of all skill levels, but also how it manages inventory and forecast for its demand. The company has devised new inventory management strategies that have become a benchmark in the electronic industry and examples to many other companies worldwide.

These newly implemented benchmarks not only minimized inventory costs, but simultaneously helped Apple smoothly sail through high profile product launches without giving scope to competitors or allow them to catch up with competitively similar products. The case not only covers inventory management techniques at Apple, but also provide basis for calculating the internal fund requirements of the company based on projected sales.

In the electronics business, companies desire to minimize inventory storage as much as possible to avoid the risk that it won’t move to consumer hands. However, when a company underestimates the anticipated demand of a product and produces fewer units than expected, this results in a shortage of inventory, leading to a loss in both customers and market share. Therefore, a fundamental practice for a manufacturer is to keep as little inventory on hand as possible. As Apple’s agenda is perceived, they try to keep the right balance of inventory in all of their stores to satisfy customers demand.

Marketing products quickly saves the company storage costs and avoids the devaluation of products due to the continuous improvement of technology both internally and by new innovations from competitors. The best way to keep the inventory at minimized level is to invest and focus on supply chain and marketing continuously. To increase production, it is wise to hire contractors for manufacturing equipment instead of owning one. By doing so, the company will focus on promoting the inventory management in order to sell that specific line of products speedily at the fixed price.

Tim Cook, the manager of Apple, believed inventory loses somewhere between 1-2% of its value each week under standard conditions, the same way milk goes bad soon after the carton is opened. Operating under this philosophy, he put Apple in front of other competitors, such as Dell, by improving the way of moving inventory, where he claimed that “inventory is evil”.

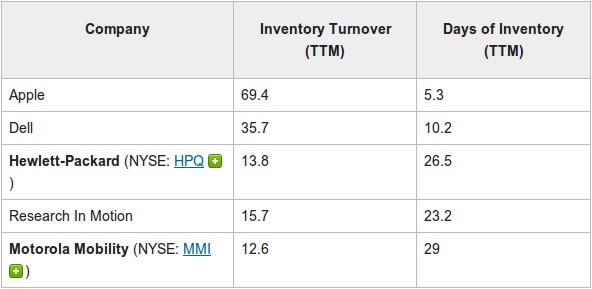

There are a few ratios that show how quickly companies can liquidate inventory. For instance, the “days of inventory” ratio measures a company’s performance and provides a better idea to investors of how long a company takes to turn its inventory into sales, with shorter periods being better. Likewise, “inventory turnover,” shows that a low turnover can mean poor sales and thus products will be sits in a warehouse losing their value; on the other hand, high turnover means strong sales and relatively empty warehouses.

What sort of inventory management practices can other companies learn from Apple, Inc.?

Sources:

H., Victor. “Apple’s Secret Sauce for Success Is Inventory Management.” Phone Arena. N.p., 29 Mar. 2012. Web. 28 Apr. 2013.

http://www.phonearena.com/news/Apples-secret-sauce-for-success-is-inventory-management_id28558

Niu, Evan. “Does Apple Have a Little Inventory Problem?” (AAPL). N.p., 5 Mar. 2013. Web. 28 Apr. 2013.

http://www.fool.com/investing/general/2013/03/05/does-apple-have-a-little-inventory-problem.aspx

“What Is Apple’s Inventory Management Secret? | QuickBooks Manufacturing Blog.”QuickBooks Manufacturing Blog. N.p., 17 Apr. 2012. Web. 28 Apr. 2013.

http://quickbooksmanufacturing.wordpress.com/2012/04/17/apple-inventory-management-secret/

I find this very interesting how Apple has inventory on hand for half the amount of time as Dell! It is amazing how smooth their system runs not only in their retails stores but also through their internet website. Personally, as a consumer of Apple, I have never run into a situation in which Apple did not have the product I hoped in stock. The affect of marketing can definitely be seen here in reducing storage costs. Perhaps this is where Dell is falling short.

I think the reason for high inventory turnover for Apple Inc. is the strategy that they are using to control inventory and its production. During the launch of the new product, Apple will have pre-order, thus they have already sell their inventory, then they will also have less inventory on hand than projected demand. In addition, I think their online orders are assembled after they are placed. Where as, in most other firms, they will have more inventory on hand during launch and also they don’t control production as tight as Apple does.

As a user of Apple and many of its products, without a doubt Apple is good at what it does and produces, their marketing, their product, and their management is top-notch. This article not only proves that, but also it shows another great advantage Apple has, which is through their inventory management, by improving the way of moving and controlling inventory and keeping inventory on minimized levels. Other companies should learn from Apple and use a similar strategy by controlling the production of their products more tightly rather than having a large amount of inventory on hand and in storage. In the end, this hurts the company not only like this article said with the storage costs and etc., but also because of the innovations with technology and new products coming out daily, that the old ones go to waste sooner than we know it.

A large amount of inventory on hand can lead to a large amount of unwanted product in the future. Apple appears to have a good strategy on how to avoid losing money with extra inventory on hand. Apple is both a good and a service so therefore the customer is involved yet not involved at the same time. Yet, Apple has shown that they are capable of handling this factor.

I found myself wondering why Dell has such a high days of inventory compared to Apple. I feel that we might have to account for the fact that Dell has an inventory that consists of a lot of individual parts, since they have to keep components on hand to build computers, and fewer finished products. I strongly agree with Apple’s Tim Cook and his idea that inventory loses somewhere between 1-2% of its value each week under standard conditions. And when we begin to talk about inventory in the millions, that’s a huge deal.

As a strategic inventory planner for a Fortune 500 company, I work closely with production, supply planners, and finance on a daily basis to optimize inventory levels for all of my company’s products. Having the right product at the right time and place in my industry is imperative as patients need critical pharmaceutical products sometimes in cases of life and death. Our policy is to never have to backorder any products since we must maintain an assurance of supply chain to meet our customers (patients) needs especially in critical care situations. This assurance does create some minute inventory fluctuations at points because we try to minimize all risks within our supply chain to alleviate bottlenecks during production. Like Apple, we manage demand forecasts and utilize long range planning to create optimal inventory strategies that align to our customer’s needs. My company and Apple are similar in the fact that they are constantly investing the supply chain to improve operational efficiency in order to allow products to move quickly through the value chain on to the customer. We constantly adjust our production plans in order to react to flexible demand projections that can change at any time. Having a proper and effective inventory management system allows the company to manage their operations better and creates more cash flow by limiting inventory levels.