Early this year, CEO of Patagonia, Casey Sheahan, raised a few eyebrows by introducing a “Don’t Buy This Jacket” campaign. Sheahan explained Patagonia must do the opposite of other businesses today for them to stay in business for a long time, as well as leaving an inhabitable planet for future generations. He goes on to say, “We ask you to buy less and to reflect before you spend a dime on this jacket or anything else.” Not only does this give a subtle hint that Patagonia strives for unparalleled quality, it shows the company highly values humanity and environmental consciousness.

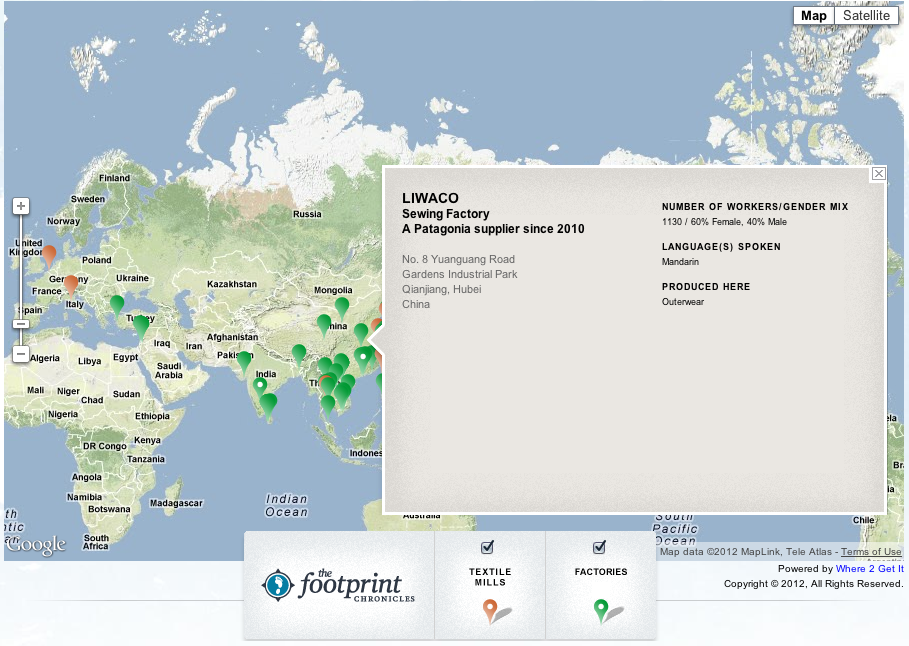

More recently however, Patagonia has gone to new lengths to prove the ingenuity of their values and offer unprecedented transparency concerning their business operations to their customers. Patagonia has introduced The Footprint Chronicles, an interactive map of the world on their website that pinpoints all of the members of its operational supply chain, both textile mills and factories. Clicking on a pinpoint on the map brings up information on the location including what they are, their exact address, what they produce, work force, gender ratio, and how long they have worked with Patagonia.

For most companies, an informational map like this could just be a marketing ploy, but for Patagonia, it is an attempt to take business practices and operations to a new level of transparency for all to see. Patagonia is well known for the labor and working condition standards it surpasses every year, but nowadays it just isn’t enough for a company to have a piece of paper saying it passed regulations. This is due to the fact that sometimes these big manufacturers seemingly meet requirements for issues surrounding labor operations and working conditions, however, they are usually the ones who end up on a negative headline about underage labor practices, poor working conditions, etc.

Patagonia has always been know to champion quality over everything; not only a quality product, but quality operations that put people and the environment over profit. According to Patagonia, there are no private/closed-off managerial offices at their locations, creating a closer link between their corporate, business, and functional levels of the company. Though it may seem Patagonia’s humanity, sustainability, and environment driven business strategy leaves little room for profit, it is not true as the company has actually doubled revenue and tripled profits since 2008 ($540 million in 12 months ending with this past April) accoring to the Los Angeles Times.

Patagonia is definitely proving that not taking the easy short-cut to profits can undoubtedly pay off in the long-run. Could this be a sign that you do not have to be inhumane, greedy, or careless of the environment for your company to turn a profit and be successful?

http://www.patagonia.com/us/footprint/