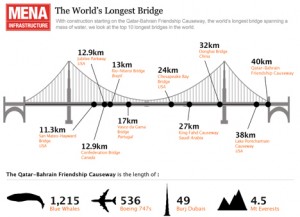

The Qatar-Bahrain Causeway is a continuously delayed project in the Arabian Gulf region. The project consists of constructing a 40km (25mi) bridge (claimed to be the longest in the world) between the Qatar and Bahrain.

Plans for the construction of the bridge were first made in 2001. The project was approved for construction in 2005, and a formal agreement between the two GCC (Gulf Cooperation Council) members was signed in 2006 to form a company, the Qatar and Bahrain Causeway Foundation, that would manage the project. Everything seemed to be on track for the project when it was revealed that construction would begin in 2008 and construction would last four years.

However, a series of events have dramatically delayed the project. The 2008 financial crisis certainly had a toll on the mega project, causing the estimated cost of the project to rise unexpectedly. In 2009, the initial plan to have the bridge accommodate motor vehicles was changed to include a railway as well. The railway itself is part of a GCC-wide railway project. Delaying one critical project can and will have significant effects on the other. Numerous re-designs to the bridge and escalating costs further delayed construction initiation from 2008 to 2011 and then to 2015, with a plan to complete the causeway shortly before the FIFA World Cup 2022 held in Qatar. Of the two countries, Qatar especially needs to manage all the projects they have at hand before hosting the world’s biggest event. This can be achieved by assigning more resources to all their projects, something not too difficult for the rich gulf state.

Politics always play a role when a project involves multiple countries. Bahrain and Qatar have had territorial disputes since the nineteenth century. One case is that of Hawar Islands, a series of islands located between the two countries. In 1939, when both countries were under British rule, London ruled that the islands belonged to Bahrain. Qatar tried to appeal the decision multiple times, only for the other GCC countries to intervene. In 2010, a Bahraini fisherman was found roaming Qatari waters, leading the Qatari coast guard to fire at his vessel. This incident reignited the dispute over the islands of Hawar. The bridge, dubbed the “Qatar-Bahrain Friendship Bridge”, ironically, may never see the light of day if these differences are never settled.

All obstacles and issues aside, the bridge will boost the economies of both countries considerably. Currently, a trip between Bahrain and Qatar can take up to five hours, and involves crossing through Saudi Arabia, which can be problematic for non-GCC nationals trying to obtain a Saudi visa. The new journey will be cut down to less than an hour.

If this project is ever completed, it will be one step closer to unifying the Gulf states as one country–a project of its own that’s been frequently discussed.

Do you think the Qatar-Bahrain Causeway will get completed before the 2022 World Cup, if ever? Is bad project management and estimation to be blamed for the delay of the bridge, or are there other factors?

Sources:

http://countrystudies.us/persian-gulf-states/44.htm

![[image]](http://si.wsj.net/public/resources/images/MK-CE130A_BRIDG_G_20130619155027.jpg)