https://www.projectsmart.co.uk/keeping-tabs-on-projects.php

After completing my project management course at DePaul, the dots began to connect. The course has created a well round view of what goes into managing a project. The various tools, skills, and resources necessary to being a successful project manager. From estimating project cost and timelines, managing risk, to scheduling resources and cost, this course has taken me from an unclear idea of what project management is to a more refine idea of what a project manager does. The experiences I have encountered while working on our group project and the individual interview helped immensely define and illustrate the responsibilities of a project manager.

Furthermore, after reading the article “Keeping Tabs on Projects,” I have drawn similarities to my experience in the group project and to Kevin Wood’s experiences (the person I interviewed) as a project manager. Projects have a lot of moving parts as I have discovered in our teams experience. I would imagine at a company, one might even have multiple projects going on simultaneously. To successfully run a project, being able to keep tabs on every aspect of the project is vital. In my experience with my group we did this extensively through emails, meetings, formal reports for class, and informal conversations over the phone/texting. In the interview with Kevin, this was one of the topics we discussed in-depth. He mentioned some days he only spends reporting on various aspects of his project, whether its to his supervisor or his client.

“Keeping Tabs on Projects” discusses implementing a systematic way to keep tabs on everything without having to dig through emails and notepads. My group did this by creating a workflow chart. Its important to keep upper management informed along the way. By doing so, it can make the project easier with them as far as support and proper resource implementation.

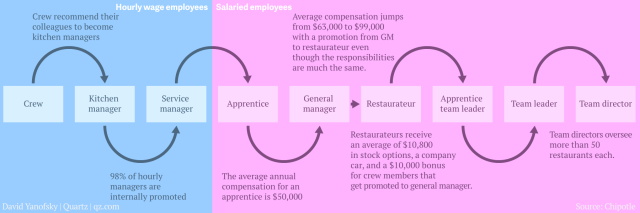

In the article it discusses that in the beginning of the project its important to identify the roles every player will be responsible for. By identifying those individuals and what roles they each will play, the project manager will understand what information they will need for further execution. By keeping tabs on the individual deliverables, it allows the project manager and the group to help identify problems and potential roadblocks. In my groups experience, I was responsible for finding potential locations for our event. By getting the appropriate information to my group early on, we were able to make a sound decision on where our event would best benefit our cause.