Three weeks ago the Rana Plaza factory building in Bangladesh collapsed, killing 1,127 people. A majority of these were workers producing garments for sale in the United States and Europe. The factory manufactured apparel for brands including Benetton and Walmart among others. An investigation revealed that the building was deemed unsafe just days before the collapse, but factory supervisors ordered their employees to continue working in these hazardous conditions.

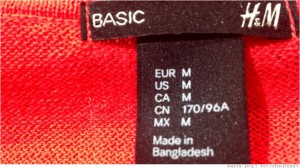

The obvious question is why a tragedy like this would occur, even after there had been a forewarning. The answer is because factories like Rana Plaza and others in Bangladesh are under immense pressure to produce a high volume of low-cost garments for their biggest buyers, Walmart, H&M, Inditex (which owns Zara), and Gap to name a few. These companies pride themselves on their ability to get apparel into stores only weeks after designing them. However, this incredible efficiency requires a tremendous amount of manual labor, and no where are labor costs cheaper than in Bangladesh. The massive global supply chains of a majority of apparel manufacturers flow through the South Asian country which trails only China in terms of garments exported. Unfortunately, most of the large Western companies are unaware of the conditions that exist in the factories where their products are being produced.

The obvious question is why a tragedy like this would occur, even after there had been a forewarning. The answer is because factories like Rana Plaza and others in Bangladesh are under immense pressure to produce a high volume of low-cost garments for their biggest buyers, Walmart, H&M, Inditex (which owns Zara), and Gap to name a few. These companies pride themselves on their ability to get apparel into stores only weeks after designing them. However, this incredible efficiency requires a tremendous amount of manual labor, and no where are labor costs cheaper than in Bangladesh. The massive global supply chains of a majority of apparel manufacturers flow through the South Asian country which trails only China in terms of garments exported. Unfortunately, most of the large Western companies are unaware of the conditions that exist in the factories where their products are being produced.

The latest tragedy has finally caught the attention of European and American companies. This past week H&M, the largest buyer of garments from Bangladeshi factories, agreed to a plan to improve fire and building safety in Bangladesh’s apparel factories. The five-year plan calls for independent safety inspections and for companies to make the findings public. Joining H&M were Inditex, the world’s biggest clothing retailer, and several other European apparel companies. However, PVH, the owner of brands such as Tommy Hilfiger and Calvin Klein, is the only American company that has signed the pact. Companies including Gap, Walmart and JC Penney have considered the plan, but have not yet signed on, mostly due to the cost and how legal issues would be resolved.

I believe this safety pact is a step in the right direction on the road to abolishing subpar working conditions around the world. Therefore, from a management perspective, I think that companies that are not signing the pact, like Walmart and JC Penney, are making a mistake. Not signing sends a negative message to consumers and investors, if the companies are unwilling to spend money to protect human lives customers will question the ethics of the company’s management. Ethics is an important facet of operations management. The managers at American apparel companies need to recognize these issues, like their European counterparts have, and address the dangerous working conditions that exist in their supply chain. I think in the long run the benefits of ensuring safe conditions for all in the supply chain will outweigh the cost.

I believe this safety pact is a step in the right direction on the road to abolishing subpar working conditions around the world. Therefore, from a management perspective, I think that companies that are not signing the pact, like Walmart and JC Penney, are making a mistake. Not signing sends a negative message to consumers and investors, if the companies are unwilling to spend money to protect human lives customers will question the ethics of the company’s management. Ethics is an important facet of operations management. The managers at American apparel companies need to recognize these issues, like their European counterparts have, and address the dangerous working conditions that exist in their supply chain. I think in the long run the benefits of ensuring safe conditions for all in the supply chain will outweigh the cost.

What is your opinion on the decision of many American companies to not sign the safety pact?

Do you think it is the duty of American companies to ensure the safety of workers in foreign countries?

Sources

http://www.businessweek.com/articles/2013-05-13/h-and-m-pledges-to-make-bangladeshi-factories-safer

http://www.ft.com/cms/s/0/79cedd4e-c000-11e2-b19c-00144feab7de.html#axzz2TmPslBBP

http://money.cnn.com/2013/05/13/news/companies/hm-bangladesh-safety/index.html

http://www.nytimes.com/2013/04/25/world/asia/bangladesh-building-collapse.html?pagewanted=1&_r=0&hp