Do you remember the Toyota recall in Bahrain? Have you ever thought what really went wrong and why Toyota is recalling those vehicles?

I’ve read an interesting paper What Really Happened to Toyota? that was analyzing the different recall acts of Toyota which took place in USA due to quality and safety issues. The paper analyzed the main reasons behind such issues as the brand image and sales revenue were severely impacted.

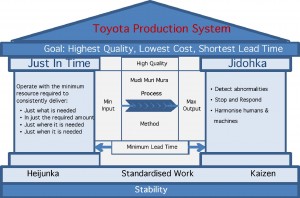

Toyota and its chain of suppliers had always pioneered quality management methodologies of total quality control since they believed that quality, customer satisfaction and profits are deeply connected. Quality is a major component of Toyota’s strategy and production system, and was always looked at as a role model by other competitors, such as Ford, GE and Honda.

So what really happened that made “Quality” suffer?

The paper states that there are two main reasons behind the quality issues:

- Toyota executive management always believed that quality should have a high priority, however, when the new management came in, their focus has changed. The new focus was on rapid growth rather than quality. As Toyota expanded in new markets, from 2003 onward their sales grew faster than the company can manage, and therefore, growth had taken priority over the traditional focus on quality. The decisions were made in favor of meeting sales, cost cutting and profit target while sacrificing product development, supplier management and production.

- The second reason is a result of the increasing complexity of car products due to technological changes. Government regulations on safety, emissions and fuel consumption and the rising customer demands for environment friendly cars with luxury features have all added to the complexity level. This point applies to other car manufacturer as well, but due to the continuous demand and market expansion, Toyota was faced with the challenge of changing its production process to meet the demand of safe, clean, fuel-efficient and comfortable cars.

Some of the process change decisions were to compress the lead time between exterior design approval and start of sales to less than 20 months. Another change in process was to introduce an accelerated design cycles that have stressed the development and production systems which have created conditions for quality failure.

Toyota’s supplier management and its performance were also affected by the above two points. To meet the rapid demand and product complexity, Toyota had to outsource engineers and contract with new suppliers because the current engineers and suppliers were not sufficient. Most of those contract engineers and suppliers were inexperienced with Toyota’s standards and practices, and they were overseas (none Japanese speakers) contacts which had lead to coordination and communication problems.

I think that for any company, risk assessment should be conducted before moving with growth and expansion decision. With Toyota, the quality has suffered because they banded their core values of quality and focused on growth.

In your opinion, what went wrong with Toyota?